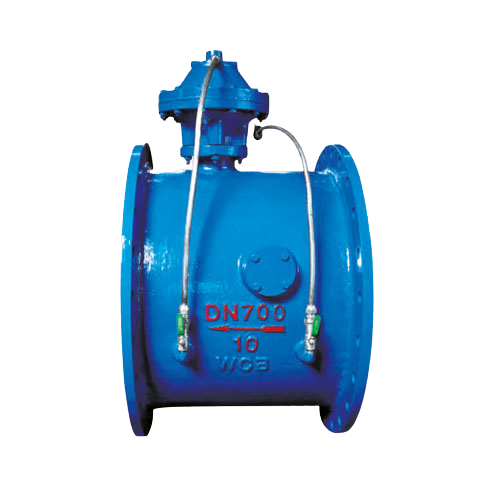

Product description:

The pipe force valve is the outlet of the water pump after the old manual control valve, hydraulic control butterfly valve, multi-functional hydraulic valve and hydraulic valve.

The fifth generation of new products after control valves such as automatic valves. Through the fluid design of the valve, a linear flow channel is formed, with low energy consumption, stable operation and good sealing effect. It has the functions of electric gate valve, electric butterfly valve and check valve. By increasing the quick closing time, it can better eliminate Water hammer hazards, protect the safety of water pumps and pipe network systems. When the hand wheel is turned clockwise, the large and small valve stems simultaneously drive the upper and lower stubble plates and compress the sleeve to close, and vice versa to open. In this way, the gate reciprocates up and down between the guide pillars to complete the valve opening and closing work. Pipe force valves are mainly used for centrifugal pumps, mixed flow pumps and axial flow pumps in automatic water supply and drainage pumping stations. The outlet pipes are designed with two control devices, piston type and diaphragm type, which can be respectively applied to clean water, raw water media, sewage, and slurry Water medium; through the auxiliary parts, real-time feedback on the online operation of the valve can be provided. There are five types of specifications, such as open type, backwater low pressure type, and sewage type, so as to meet the needs of different customers in different working conditions.

Due to its compact structure, small size and light weight, it is especially suitable for large-diameter piping systems. It can be widely used in electric power, environmental protection, metallurgy, petrochemical, water, municipal, food and other industries for supply and drainage systems, sewage pump rooms, chemical fluid and other transportation systems. It is the most novel structure, the most advanced performance and the most reliable operation at home and abroad. New control equipment for pumping stations

Installation diagram:

Installation Notes:

1. The pipe force valve can be installed vertically or horizontally. In order to facilitate installation and maintenance, in the space

When permitting, priority should be given to horizontal installation, and the valve shaft should be guaranteed to be horizontal.

2. When the valve is closed, the smooth surface of the valve plate is in the direction of the inlet.

The face is the exit direction. Reverse installation is strictly prohibited. The distance from adjacent valves and bends should not be less than 1DN.

3. In horizontal installation, in order to improve the stress condition of the pipeline, when the valve diameter is greater than 900mm,

In order to improve the stress situation of the pipeline, support or foundation can be set.

The main technical parameters:

Main external dimensions and connection dimensions: