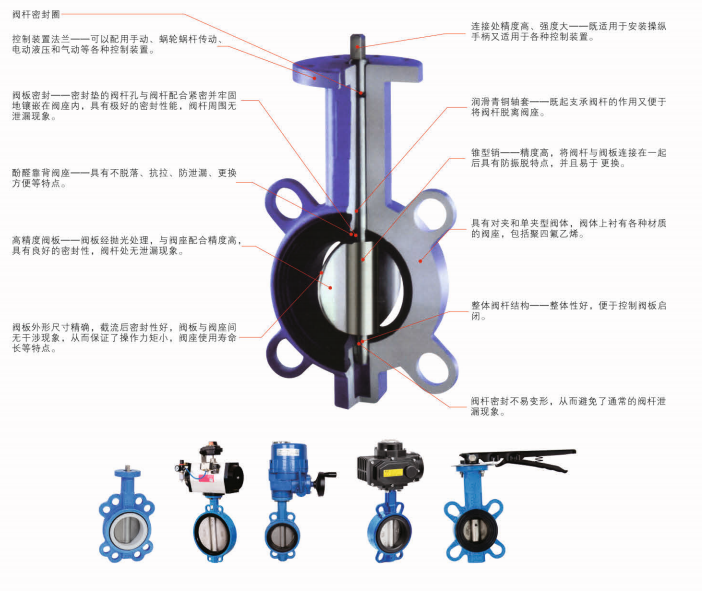

Product Introduction:

The A-type and LT-type D(3/6/9)71 butterfly valves produced by our factory have introduced advanced foreign technology, have many years of production history of this product, and have won national quality awards for many times. The transmission methods include; handle, worm gear transmission, pneumatic, electric, etc. The diameter range is DN25~DN1200.

Our butterfly valves can be used in the pipelines of petroleum, chemical industry, food, medicine, papermaking, hydropower, shipbuilding, water supply and drainage, metallurgy, energy and other systems, and are suitable for various corrosive gases, liquids, semi-liquids and solid powder media.

Features:

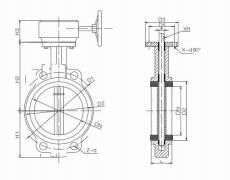

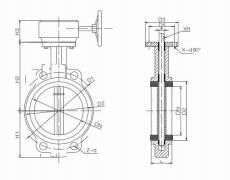

The butterfly valve is mainly composed of a valve body, a rotating shaft, a valve plate, a valve seat and a driving mechanism (handle, worm gear, pneumatic device or electric device). The driving mechanism drives the shaft and the butterfly plate to rotate to achieve the purpose of opening and closing and controlling flow. Its characteristics are as follows:

1. Simple and compact structure, small and light, easy to transport, install and disassemble;

2. 90° opening and closing, quick switching. Small operating torque, labor-saving and light;

3. Good sealing performance, long service life and zero leakage;

4. Choose different parts materials, which can be applied to a variety of media;

5. The flow characteristic is similar to a straight line, and the regulation performance is good.

The main technical parameters:

Material of main parts: