The elastic seat sealing gate valve, also known as the resilient seat gate valve, is a type of valve that is commonly used in various industries. It is designed with an elastic seat, which allows for a tight seal between the gate and the seat, preventing any leakage.

This type of valve is particularly suitable for applications where a positive shut-off is required, such as in water treatment plants, wastewater systems, and oil and gas pipelines. The elastic seat sealing gate valve can handle a wide range of fluids, including water, gas, and oil.

Product description:

For a long time, the general gate valves used in the market have generally suffered from water leakage or rust. The elastic seat seal gate valve produced by the company by introducing European high-tech rubber and valve manufacturing technology has overcome the poor sealing, elastic fatigue, rubber aging and production of general gate valves. Defects such as rust, the elastic seat seal gate valve uses the compensation effect of the elastic valve to produce a small amount of elastic deformation to achieve a good sealing effect. The valve has significant advantages such as light switch, reliable sealing, good elastic memory and long service life. It can be widely used as a regulating and intercepting device on fluid pipelines such as tap water, sewage, construction, petroleum, chemical industry, food, medicine, textile, electric power, shipbuilding, metallurgy, and energy systems.

light weight:

The valve is made of resin sand molded nodular cast iron material, which has high strength and small size, and its weight is about 20%~30% lighter than traditional gate valves. It is easy to install and maintain.

Flat bottom seat:

The traditional gate valve usually has a recessed seat, which increases the fluid resistance, and is easy to accumulate welding slag, stones, sediment and other debris, which is not conducive to sealing and flow surface. The elastic seated gate valve produced by our company adopts the flat-bottomed full-water domain straight-through design, which is quite straight, and is not easy to accumulate sundries, ensuring reliable sealing and unimpeded fluid flow.

The whole disc is glued:

The disc is made of high-quality rubber for the overall internal and external coating. European first-class rubber vulcanization technology enables the vulcanized valve to ensure accurate geometric dimensions, and the rubber and ductile iron disc are firmly bonded, not easy to fall off and have good elastic memory.

Precision casting valve body:

The valve body is made of precision casting, and the precise geometric dimensions make it possible to ensure the tightness of the valve without any processing inside the valve body. The gate frame is made of ductile iron, covered with rubber as a whole, with precise geometric dimensions, firm covering, no falling off, good elastic memory, and interchangeability.

preservative:

The inner and outer surfaces of the valve are coated with powder epoxy resin, and the internal parts are made of stainless steel or copper alloy to prevent corrosion and rust of the valve body, and can be used in sewage systems. And underground and other harsh environments.

Not fragile:

In the past, traditional cast iron gate valves were often broken due to foreign objects hitting, colliding or heavy pressure. Since the main body is changed to ductile iron, this situation can be greatly reduced.

'O' ring seal:

Since the valve body is sealed with three 'O' rings, it can reduce the frictional resistance when switching, greatly reduce the phenomenon of water leakage and can replace the sealing rings without stopping the water supply.

Conducive to health drink:

Since the inside of the valve body is coated with non-toxic epoxy resin, the inner and outer surfaces of the valve disc are completely covered with rubber so that there will be no rust or corrosion, and it can be used for raw drinking.

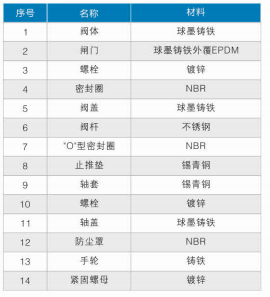

Material of main parts:

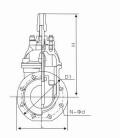

| select | Inquiry | Type | DN | D | D1 | n-φd | L | H | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 1.0/1.6Mpa | 1.0Mpa | 1.6Mpa | 1.0Mpa | 1.6Mpa | ||||||

| RVC(H)V-0050 | 50 | 165 | 125 | 125 | 4-19 | 4-19 | 178 | 340 | ||

| RVC(H)V-0065 | 65 | 185 | 145 | 145 | 4-19 | 4-19 | 190 | 370 | ||

| RVC(H)V-0080 | 80 | 200 | 160 | 160 | 8-19 | 8-19 | 203 | 410 | ||

| RVC(H)V-00100 | 100 | 220 | 180 | 180 | 8-19 | 8-19 | 229 | 450 | ||

| RVC(H)V-00125 | 125 | 250 | 210 | 210 | 8-19 | 8-19 | 254 | 480 | ||

| RVC(H)V-00150 | 150 | 285 | 240 | 240 | 8-23 | 8-23 | 267 | 550 | ||

| RVC(H)V-00200 | 200 | 340 | 295 | 295 | 8-23 | 12-23 | 292 | 630 | ||

| RVC(H)V-00250 | 250 | 405 | 350 | 355 | 12-23 | 12-28 | 330 | 750 | ||

| RVC(H)V-00300 | 300 | 460 | 400 | 410 | 12-23 | 12-28 | 356 | 820 | ||

| RVC(H)V-00350 | 350 | 520 | 460 | 470 | 16-28 | 16-28 | 381 | 980 | ||

| RVC(H)V-00400 | 400 | 580 | 515 | 525 | 16-28 | 16-31 | 406 | 1010 | ||

| RVC(H)V-00450 | 450 | 640 | 565 | 585 | 20-28 | 20-31 | 432 | 1270 | ||

| RVC(H)V-00500 | 500 | 715 | 620 | 650 | 20-28 | 20-34 | 457 | 1270 | ||

| RVC(H)V-00600 | 600 | 840 | 725 | 770 | 20-31 | 20-37 | 508 | 1390 | ||